Filter Bag, Filter Cloth Manufacturing

- Homepage

- Filter Bag, Filter Cloth Manufacturing

Filter Bag, Filter Cloth Manufacturing

What Does Fora Filter Manufacture?

At Fora Filter, we specialize in the design and production of industrial air filtration components and systems, offering a comprehensive range that includes:

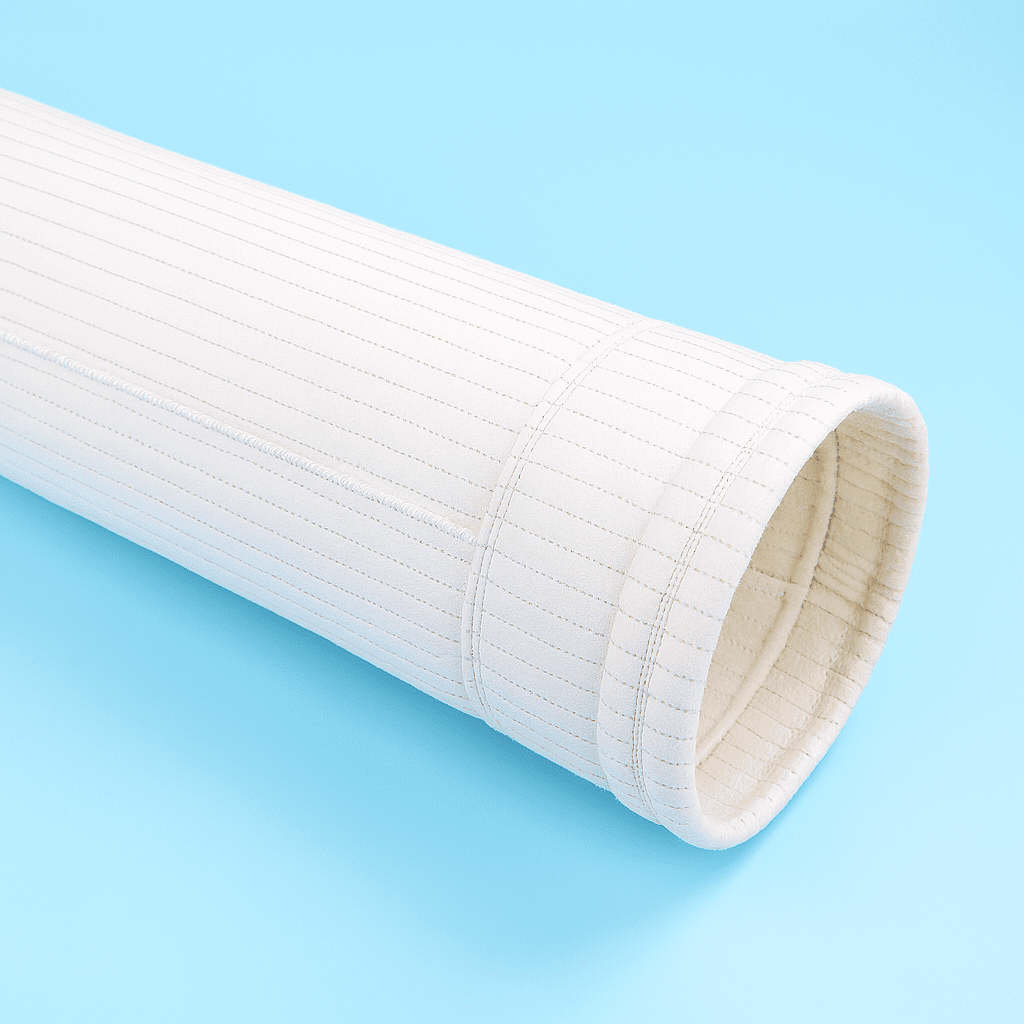

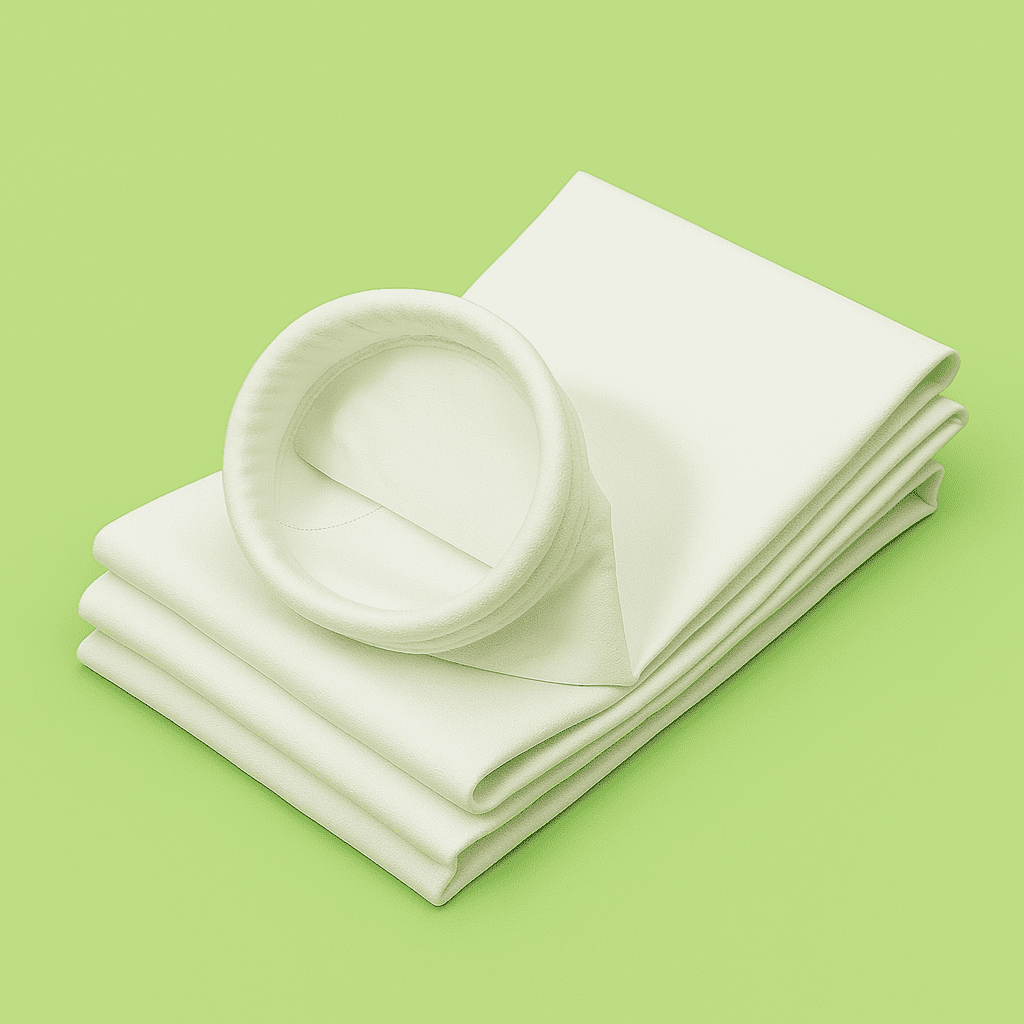

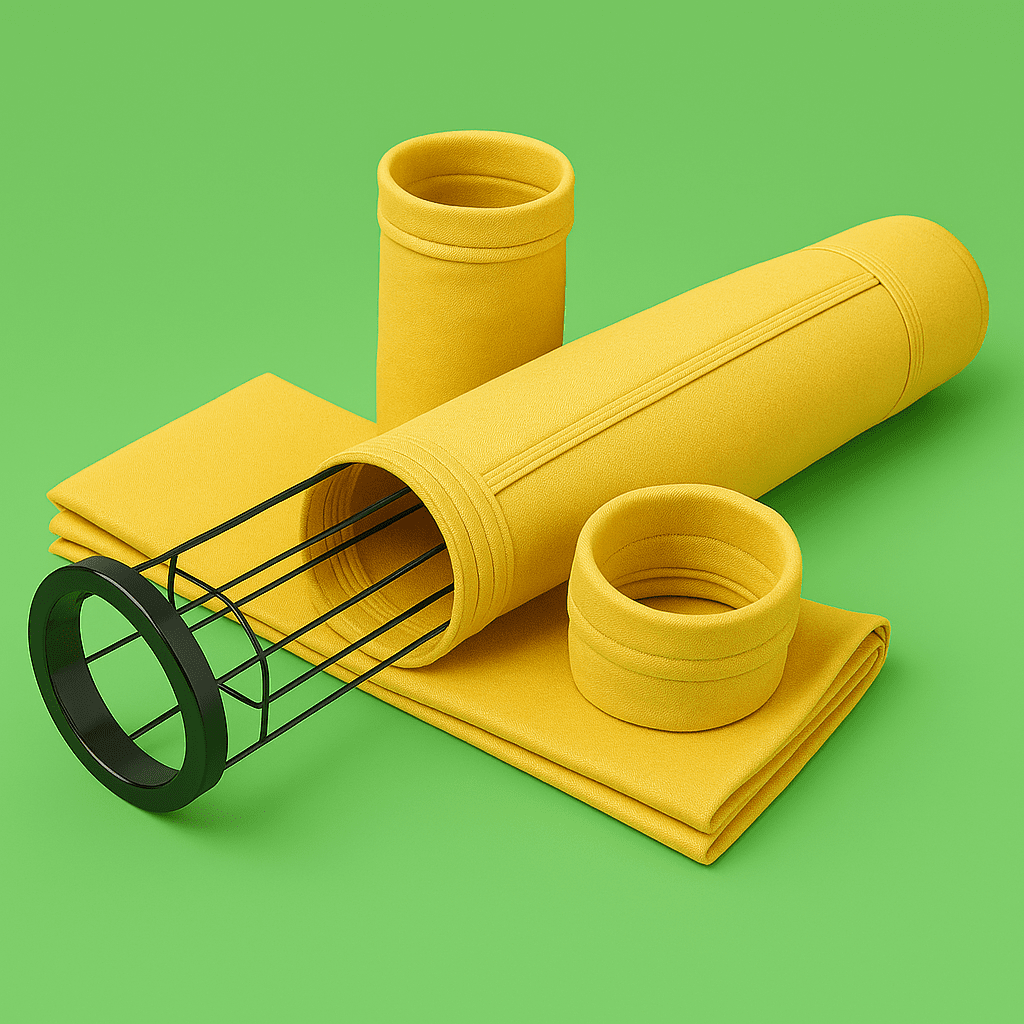

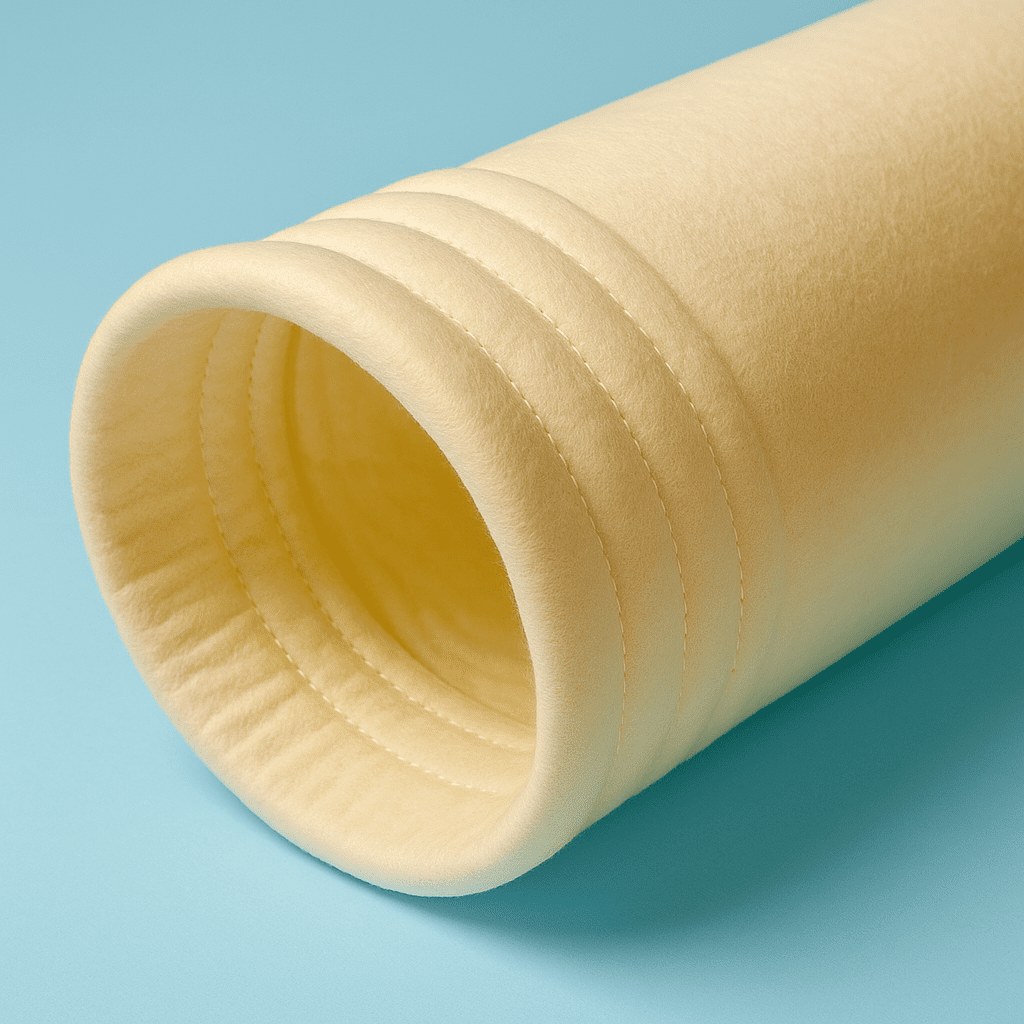

Filter Bags

Filter Fabrics (Needle Felt & Technical Textiles)

Filter Cages (Support Structures)

Complete Jet Pulse Filtration Systems

Our filtration products are engineered to capture and retain dust, fumes, and airborne particulates generated during industrial operations—effectively preventing their release into the atmosphere. In a world shaped by mass production and increasing environmental awareness, air filtration plays a vital role in protecting both the environment and human health.

How Are Filter Bags Manufactured?

The production of filter bags involves a highly controlled, multi-stage process designed to ensure performance, durability, and system compatibility:

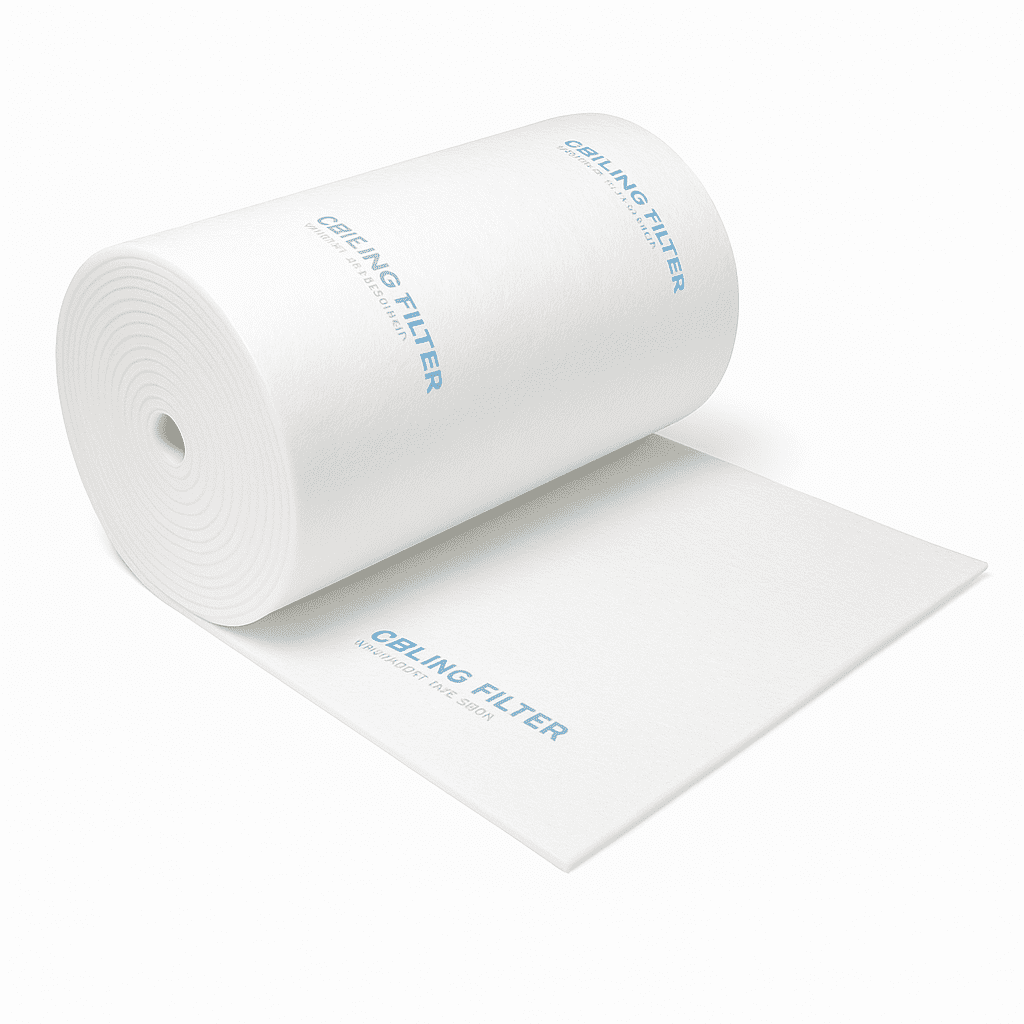

Raw synthetic fibers (e.g., polyester, Nomex, PTFE) are processed through needle punching machines to form nonwoven filter fabric.

The fabric is treated with hydrophobic and oleophobic solutions, making it resistant to moisture and oil-based particulates.

One surface is then processed through a glazing or calendering unit to create a smooth finish that prevents dust adhesion and improves cleaning performance.

The treated fabric is rolled into industrial-sized spools.

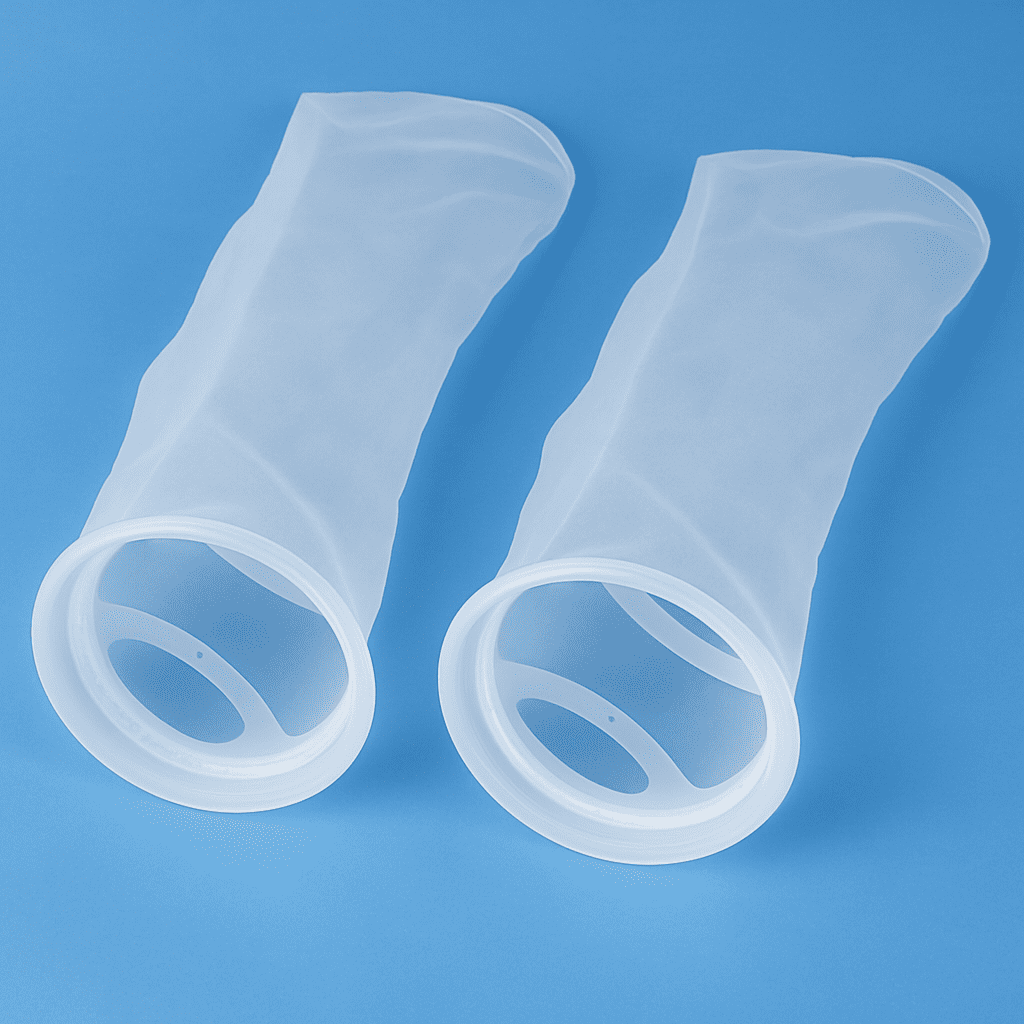

Based on system specifications, the fabric is cut and sewn using three-thread chain-stitch machines to form cylindrical bags.

A bottom cap is sewn at the lower end, and a flexible collar or snap band is attached to the top, enabling a secure fit with filter cages and venturis.

Bags undergo final inspection, cleaning, and packaging before shipment.

Every bag is custom-produced to meet system-specific requirements, ensuring perfect fit, mechanical integrity, and optimal filtration performance.

How to Select the Right Filter Bag?

Each industry operates under unique conditions such as temperature, airflow, particle size, and chemical exposure. Choosing the correct filter bag material is essential to ensure:

Long-term durability

Filtration efficiency

Operational safety

System compatibility

Below is a guide to common filter bag materials and their performance characteristics:

1. Polyester Filter Bag

Continuous Operating Temperature: up to 150°C

Applications: Widely used across iron & steel, wood processing, chemical, cement, paper, and general manufacturing industries

Advantages: Economical, versatile, resistant to mild acids and alkalis

2. Meta-Aramid (Nomex) Filter Bag

Continuous Operating Temperature: up to 200°C

Peak Temperature: up to 220°C

Applications: Asphalt production, foundries, steel plants

Advantages: Excellent thermal resistance and dimensional stability

3. Antistatic Filter Bag

Applications: Cement plants, metal processing, woodworking, grain silos, fertilizer and mining industries

Advantages: Contains conductive fibers to prevent static discharge; reduces risk of fire or explosion in flammable dust environments

4. PTFE (Teflon) Filter Bag

Continuous Operating Temperature: up to 260°C

Applications: Chemical production, pharmaceutical, high-corrosive processes

Advantages: Outstanding resistance to chemicals, oxidation, hydrolysis, and high temperatures

5. Fiberglass Filter Bag

Continuous Operating Temperature: up to 275°C

Applications: Thermal power plants, incinerators, kilns, glass and ceramic manufacturing

Advantages: Excellent heat resistance, mechanical strength at high temperatures

Note: Higher cost; used in critical applications

6. P84 (Polyimide) Filter Bag

Continuous Operating Temperature: up to 260°C

Applications: Industrial furnaces, smelting operations, aggressive dust collection

Advantages: Exceptional resistance to acids, alkalis, solvents, hydrolysis, and oxidizing environments

Why Partner with Fora Filter?

At Fora Filter, we not only manufacture filter bags—we provide end-to-end filtration solutions tailored to your industry, process conditions, and performance goals. From material selection and design consultation to production and implementation, our expert team ensures you receive a filtration system that works efficiently, safely, and sustainably.

For technical consultation, product selection, or custom manufacturing, feel free to contact our team via email, phone, or WhatsApp.