Filter Systems

- Homepage

- Filter Systems

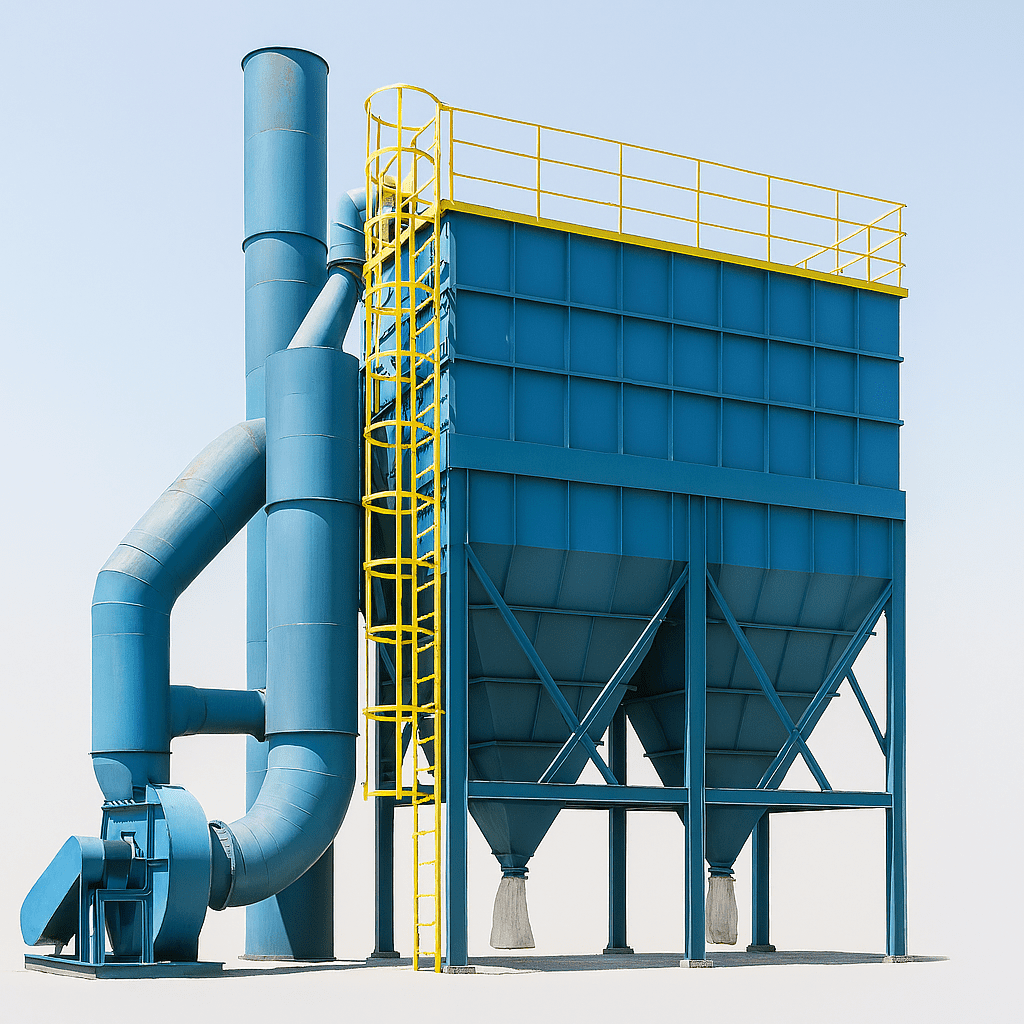

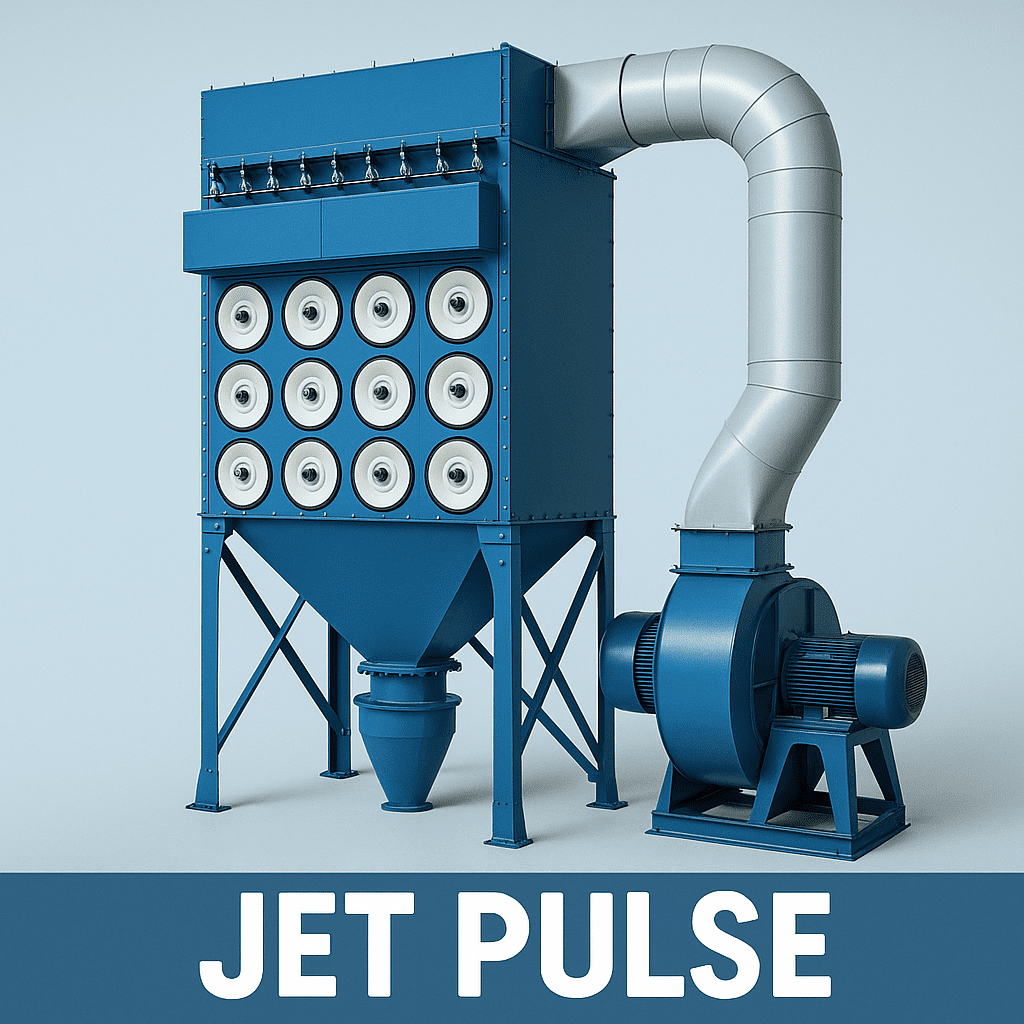

What Is a Jet Pulse Bag Filter?

A Jet Pulse Bag Filter is a high-efficiency, fully automated air filtration system specifically designed to capture and remove dust, smoke, and airborne pollutants generated during industrial production processes. These systems play a critical role in maintaining occupational health standards, meeting environmental regulations, and improving overall air quality within industrial environments.

Jet pulse filters utilize compressed air pulses to clean the filter bags during operation, allowing for continuous, uninterrupted filtration without manual intervention—making them ideal for demanding industrial applications.

Where Are Jet Pulse Filters Used?

Jet pulse bag filters are widely used across industries that involve intensive material handling and dust generation. Key sectors include:

Iron and Steel Plants

Cement and Lime Production

Aluminum and Lead Processing

Woodworking and Furniture Manufacturing

Battery Manufacturing Facilities

Animal Feed and Grain Processing

Foundries and Paint Shops

They are particularly effective in applications such as dust collection, flue gas filtration, and emissions control, ensuring safe, clean air discharge from production lines.

How Does a Jet Pulse Bag Filter Work?

The system operates on a self-cleaning principle using pulse-jet technology:

Dust-laden air enters the filter housing through the inlet duct and flows into the hopper.

A deflector plate reduces the speed of incoming air, allowing heavier particles to settle before they reach the filter bags.

Lighter particles remain suspended and are captured on the outer surface of the filter bags.

At set intervals, compressed air pulses (6–7 bar) are injected into the bags via solenoid-controlled pulse valves.

The sudden burst of air expands the bags, dislodging accumulated dust from their surface.

The dislodged dust falls into the collection hopper, from where it is either recycled or safely disposed of.

Clean air passes through the filter media, exits through the outlet duct, and is safely released by an exhaust fan.

This continuous cleaning cycle ensures maximum filtration efficiency without system downtime.

Technical Features & Project-Specific Design

At Fora Filter, we engineer custom-designed jet pulse filter systems tailored to your production environment, air properties, and dust characteristics. Key technical capabilities include:

Airflow capacity: 1,000 m³/h – 1,000,000 m³/h

Filtration area: 10 m² – 12,500 m²

Operating temperature: -30°C to +260°C

Dust types supported: Acidic, basic, flammable, and corrosive particulates

Particle size range: 5 microns – 5 mm

Modular configuration: Scalable to match capacity growth

EPASS™ system: Energy-saving integration for optimized power consumption

Project-based customization: System design adapted to space, airflow, and emission needs

Innovative integration: Compatibility with modern control and automation systems

Tailored Solutions for Your Industry

Each industrial facility has unique operational requirements, from airflow volumes to dust chemistry. Selecting the right filtration system is essential for:

Regulatory compliance

Worker safety

Energy efficiency

Maintenance optimization

System reliability

Our experienced engineering team at Fora Filter offers end-to-end support—from technical analysis and material selection to system design, production, and implementation. We ensure the best-fit solution for your specific production processes, dust load, and environmental goals.

For a cleaner, safer, and more efficient facility—trust Fora Filter’s expertise in industrial air filtration.