Filter Cloth Manufacturers

- Homepage

- Filtration

- Filter Cloth Manufacturers

Filter Cloth Production Process

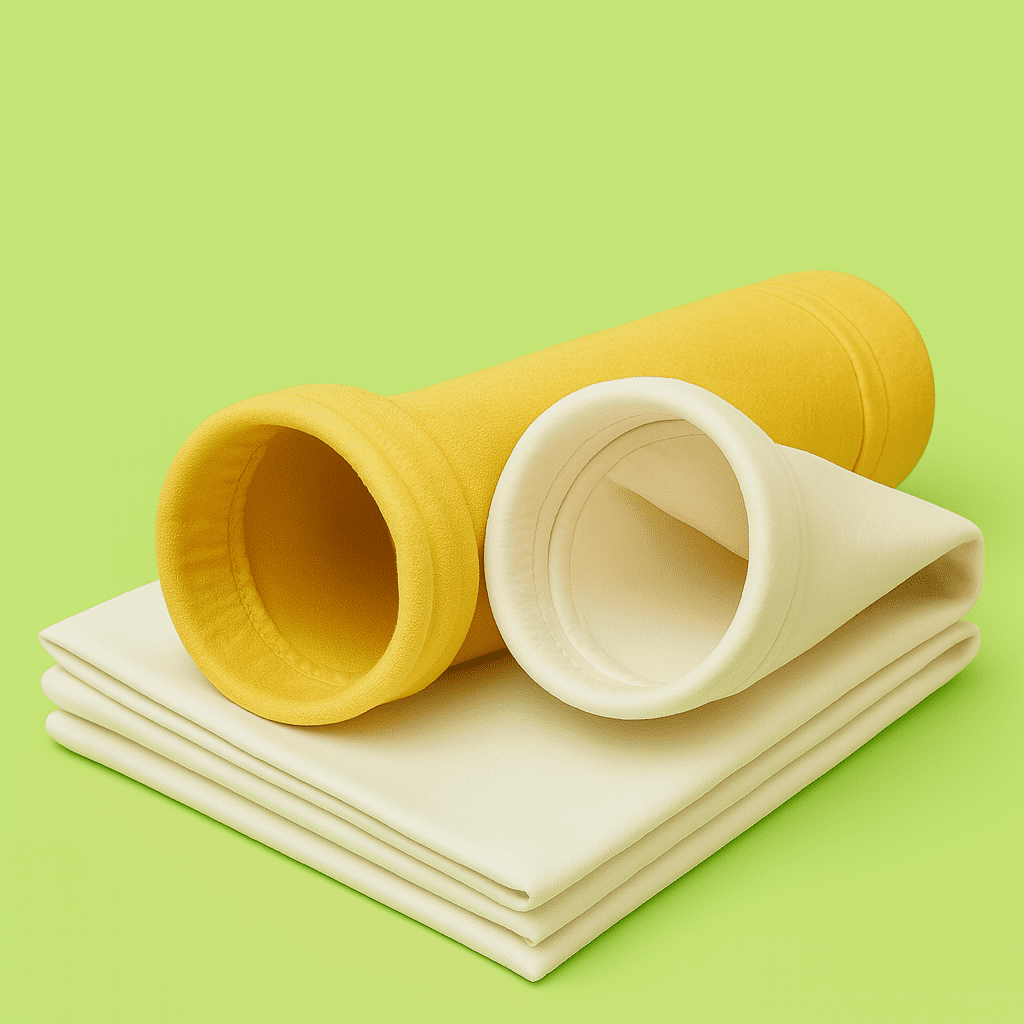

At Fora Filter, our filter cloth production process is designed to meet the demanding needs of industrial filtration systems—particularly those used in jet pulse or jet filter systems. The process begins by converting high-performance technical fibers into durable filtration fabrics using a needle punching method. This mechanical interlocking of fibers forms a robust, porous structure capable of capturing industrial dust and particulate matter with high efficiency.

To ensure maximum filtration performance, the raw fabric is subjected to specialized surface treatments:

First, the material is immersed in hydrophobic and oleophobic impregnation solutions, which provide excellent resistance to moisture and oil.

Then, a glazing (gaze) process is applied to one surface of the fabric. This creates a smoother finish, preventing dust accumulation and enhancing the self-cleaning functionality of the final filter bag.

Once the filter fabric is fully processed, it is rolled into spools and cut to order-specific dimensions. These precision-cut pieces are then sent to vertical stitching lines where they are stitched lengthwise to prepare them for conversion into finished filter bags.

Material Selection: Engineered for Application-Specific Demands

Choosing the right filter cloth begins with understanding the working conditions of the filtration system. Several parameters must be carefully analyzed, including:

Operating temperature

Chemical properties of the dust

Moisture and humidity levels

Dust particle size and concentration

Airflow rate and pressure

Location and orientation of the filtration system

Based on this analysis, our engineers recommend the most suitable filter cloth material to ensure long-term performance and durability. Available material options include:

Polyester

Nomex (Meta-Aramid)

Antistatic Filter Media

Polypropylene (PP)

Glass Fiber

P84 (Polyimide)

PTFE (Teflon)

Acrylic Homopolymer

Each roll of filter cloth undergoes comprehensive quality control before being packaged and prepared for shipment. We ensure that every batch meets both technical specifications and operational standards.

Contact Us for Technical Support and Custom Pricing

Filter cloth pricing varies depending on factors such as material type, roll dimensions, surface treatments, and order volume. For accurate pricing and product guidance tailored to your specific filtration system, we encourage you to consult our expert team.

You can reach us via email, phone, or WhatsApp for:

Technical consultation

Material recommendations

Custom quotations

Application-specific product advice

Let Fora Filter help you select the optimal solution for your dust collection and air filtration systems—engineered for performance, durability, and compliance.