Filter Fabric

- Homepage

- Filtration

- Filter Fabric

How Is Filter Cloth Manufactured?

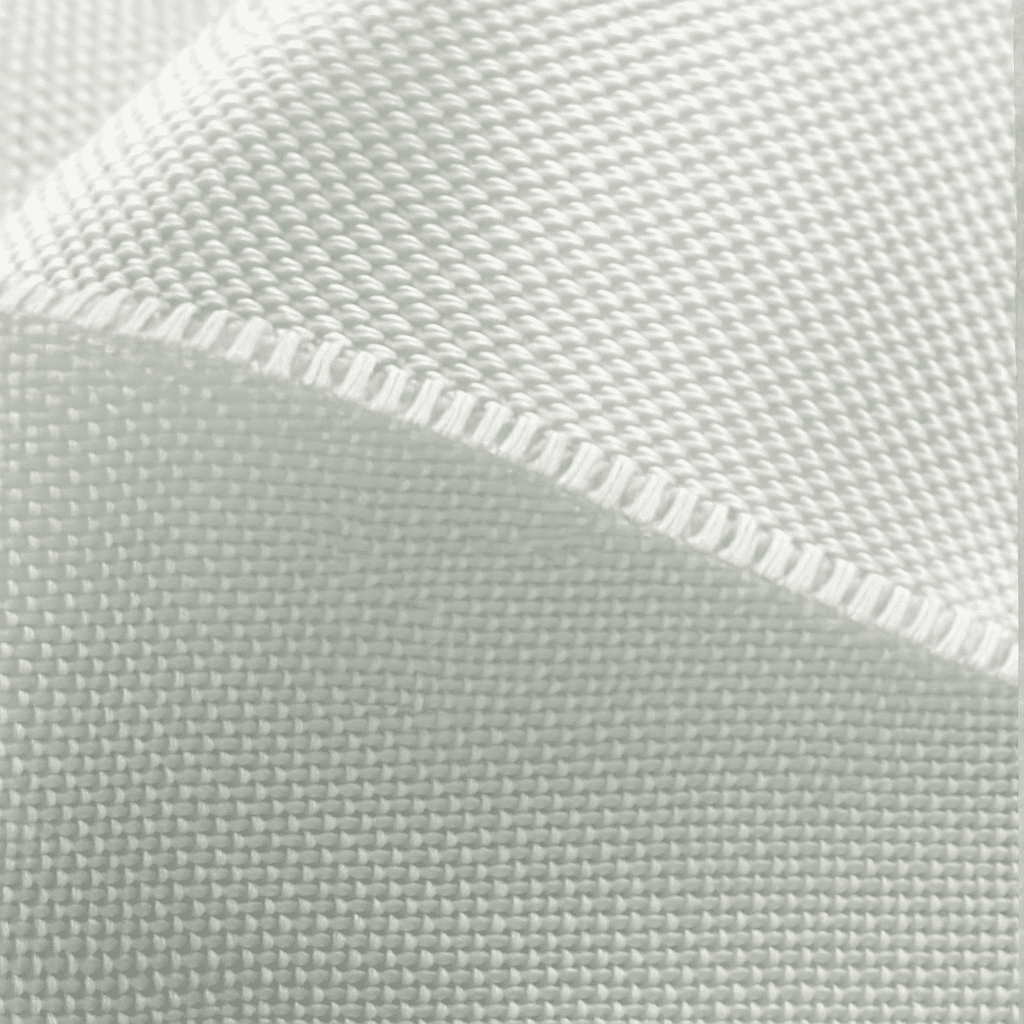

At Fora Filter, the production of industrial filter cloth is a highly controlled process that begins with the transformation of raw fiber materials—such as polyester, meta-aramid (Nomex), cotton, fiberglass, or polyimide (P-84)—into robust filtration fabrics using needle punching technology. This mechanical process entangles the fibers to form a uniform, high-strength nonwoven fabric specifically engineered for dust collection systems in industrial environments.

To enhance the fabric’s performance and longevity, the following surface treatments are applied:

- Hydrophobic and oleophobic impregnation: The needle-punched fabric is immersed in advanced treatment solutions to gain water- and oil-repellent properties. This increases resistance to moisture, humidity, and oily particulate matter.

- Glazing (gaze) process: One surface of the fabric is smoothed to prevent dust particles from adhering to the cloth, which also improves air permeability and facilitates cleaning within jet pulse systems.

After treatment, the filter cloth is dried, stabilized, and wound into rolls. These rolls are then cut to custom widths and lengths based on system specifications. Cut pieces are layered and transferred to the sewing department, where they are assembled into filter sleeves using high-strength chain-stitch machines.

The fabrication process is finalized with:

- Bottom cap sewing (to seal the bag)

- Top collar or cuff sewing, designed to securely fit with the system’s filter cage and venturi interface

Each finished filter bag is thoroughly inspected, cleaned of excess threads, and packaged for delivery in accordance with client specifications.

Industries That Use Filter Cloth

Filter cloth is a critical component in dust collection and air filtration systems used across a wide range of industries. Our filter bags are engineered to perform reliably under varied process conditions in sectors such as:

- Iron & steel

- Cement

- Aluminum

- Asphalt plants

- Woodworking, sawdust and chip collection

- Foundries

- Thermal power plants

- Chemical manufacturing

- Paper production

- Fertilizer plants

- Mining and lime production

- Food processing

- Ceramics

- Plastics and PVC

- Rubber and tire manufacturing

- Glass industries

- Paints, varnishes, and coatings

- Furniture and panel manufacturing

- Crushing & screening facilities

- Waste and recycling plants

- Heavy metal and smelting industries

From small-scale workshops to large industrial facilities, Fora Filter provides tailored solutions that address sector-specific needs with precision and reliability.

Why Proper Filter Bag Selection Matters

Choosing the appropriate filter bag is essential for ensuring system efficiency, process continuity, and regulatory compliance. A mismatch in material type, temperature resistance, or chemical compatibility can lead to:

- Reduced filtration efficiency

- Premature bag failure

- System malfunctions or unplanned downtime

- Increased maintenance and environmental risk

At Fora Filter, our experienced engineering team evaluates all critical parameters—including dust composition, working temperature, chemical exposure, and air volume—to help you identify the most suitable filter cloth solution for your operation.

Contact Us for Expert Guidance

To learn more about our filter cloth solutions, request technical specifications, or receive a custom quotation:

Email: info@forafilter.com

WhatsApp: +90553 636 4071

Let Fora Filter be your trusted partner in high-performance filtration systems—engineered for cleaner air, safer operations, and long-term efficiency.