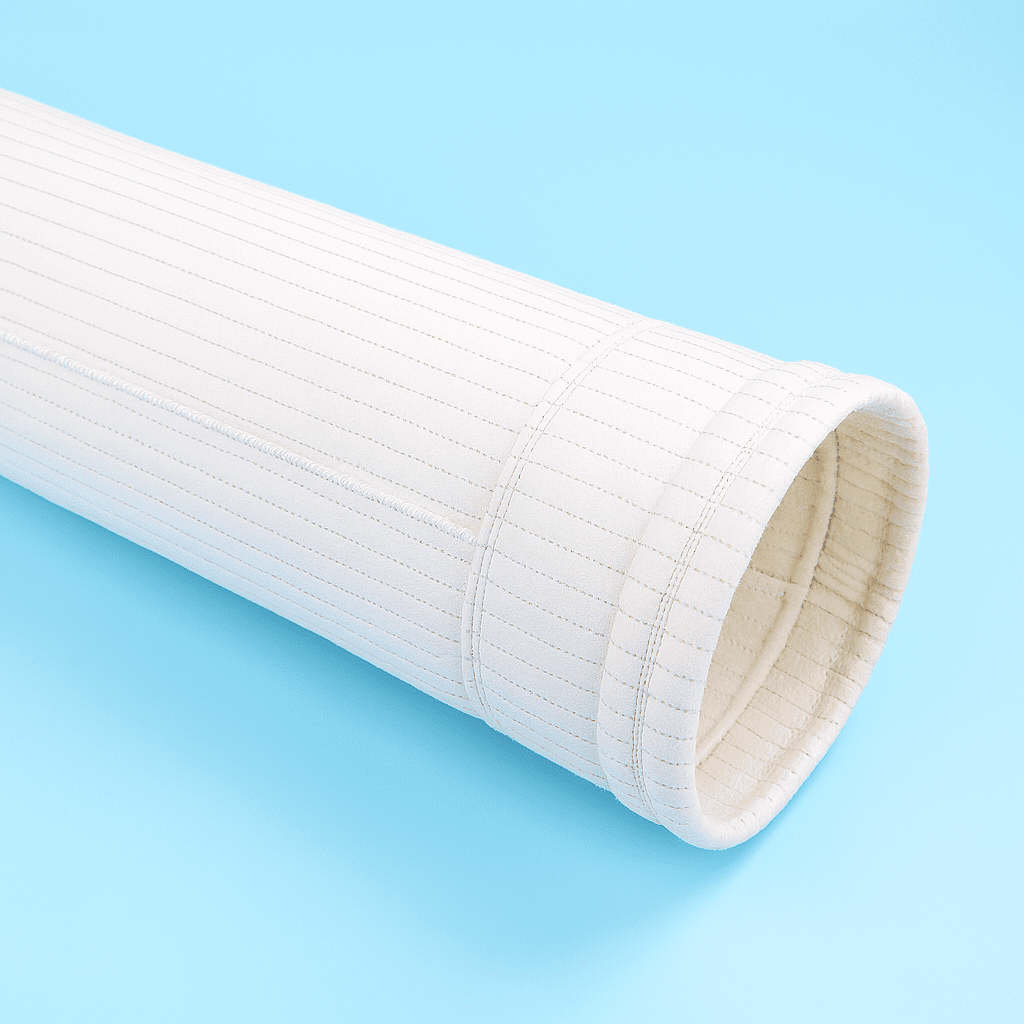

Antistatic Filter Bag Features

- Homepage

- Filter Bags

- Antistatic Filter Bag

Antistatic Filter Bag Features

| CONTENT | 100% POLYESTER ANTISTATIC |

| INNER TEXTURE | POLYESTER ANTISTATIC |

| WEIGHT | 550 g/m² ± 5% |

| AIR PERMEABILITY | 4,000 lt/dm²/hour (Dp:200 Pa) |

| THICKNESS | 2.5 mm |

| TENSILE STRENGTH | Warp: 110 kgf/5 cm - Weft: 140 kgf/5 cm |

| SURFACE TREATMENT | CALENDER AND GLAZE TREATMENT, WATER AND OIL REPELLENT HYDROPHOBIC IMPREGNATION |

| OPERATING TEMPERATURE | CONTINUOUS 130°C DRY TEMPERATURE |

| ACID RESISTANCE |

MODERATE

|

| ALKALI RESISTANCE |

WEAK

|

| HYDROLYSIS RESISTANCE |

WEAK

|

| SOLVENT RESISTANCE |

EXCELLENT

|

| OXIDATION RESISTANCE |

EXCELLENT

|

What Is an Antistatic Filter Bag?

Antistatic filter bags are engineered filtration components specifically designed to safely dissipate static electricity generated by the flow of electrically charged air and dust within industrial filtration systems. In processes such as plastic manufacturing, grain milling, and wood processing, fine particulates and airflow frequently combine to create electrostatic fields, which may result in sparks or even explosions if not properly controlled.

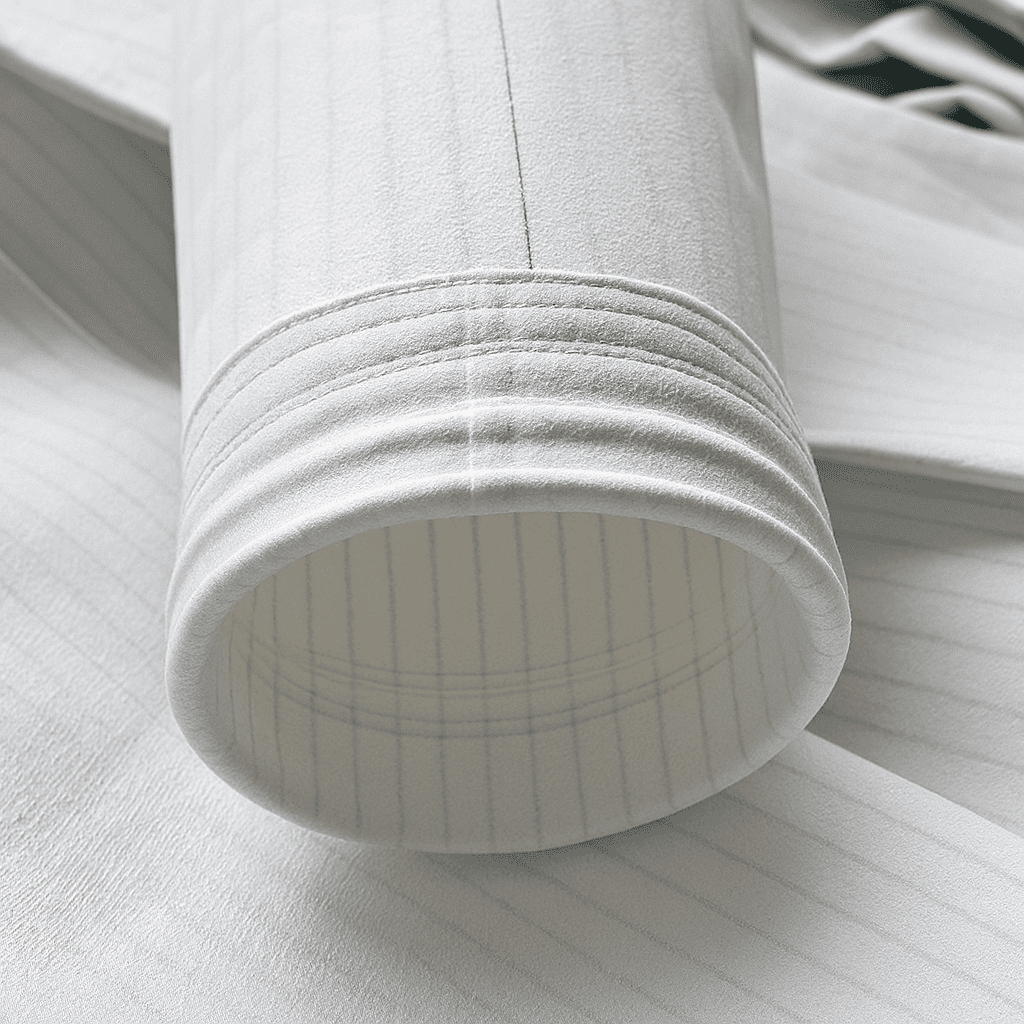

To prevent such risks, these filter bags are manufactured with conductive fibers woven or embedded into the fabric structure. These fibers safely channel static charges away from the system, protecting both the filter cage and the filtration unit from ignition risks—thus ensuring safe, reliable, and long-term operation.

Technical Specifications

Antistatic filter bags are typically produced using polyester needle-felt, enhanced with conductive filaments for static dissipation. These materials combine mechanical strength with electrostatic safety, making them suitable for dust collection systems in high-risk environments.

Key Features:

-

Base Material: Polyester with integrated conductive fibers

-

Surface Treatments: Hydrophobic and oleophobic impregnation, plus calendering

-

Fabric Weight: ~550 g/m²

-

Continuous Operating Temperature: Up to 130°C

-

Acid Resistance: Moderate

-

Solvent & Oxidation Resistance: Excellent

Surface treatments such as hydrophobic impregnation and glazing prevent moisture and oil absorption, reduce dust accumulation, and facilitate efficient cleaning through jet pulse systems.

Industries That Require Antistatic Filter Bags

Antistatic filter bags are vital in industries where static charge accumulation is common due to material properties and high-velocity air movement. Typical application areas include:

-

Plastic manufacturing and granule handling plants

-

Flour mills and grain processing facilities

-

Wood and sawdust filtration systems

-

Fertilizer production plants

-

Lead and heavy metal processing units

-

Melting, casting, and foundry environments

-

Gypsum and composite material lines

-

Powder coating and polishing units

These filter bags play a crucial role in minimizing the risk of fire or explosion, especially in dust-prone, combustible environments.

Why Expert Consultation Matters

Incorrect selection of filter bags—especially in systems with flammable dust or conductive materials—can result in:

-

Increased system maintenance

-

Reduced filtration efficiency

-

Safety hazards, including fire or explosion risks

-

Potential downtime and equipment damage

At Fora Filter, we offer specialized technical consultation to help you select the most suitable filter bag material and design based on your industry, dust characteristics, and system layout. Our expert engineers are here to ensure safety, compliance, and maximum filtration performance.