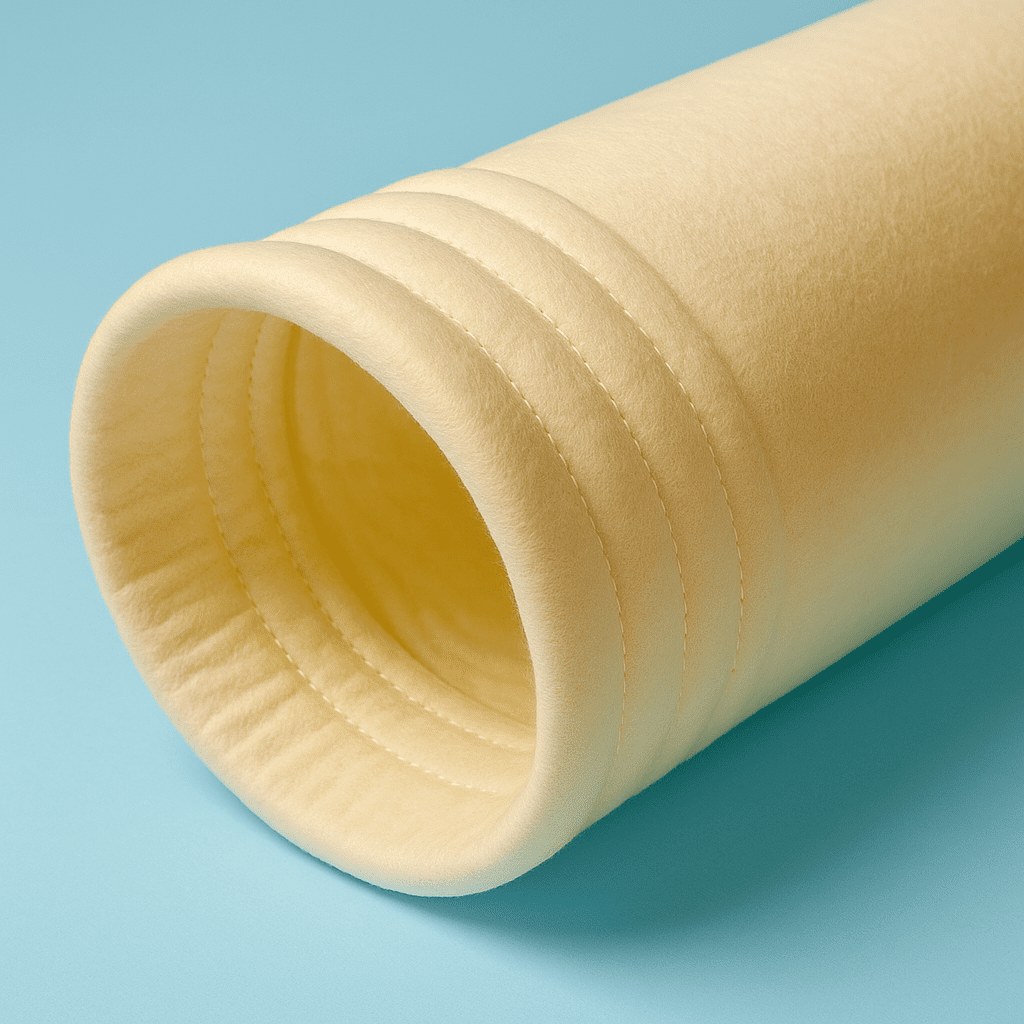

Acrylic Homopolymer Filter Bag

- Homepage

- Filter Bags

- Acrylic Homopolymer Filter Bag

Acrylic Homopolymer Filter Bag Features

| CONTENT | 100% ACRYLIC HOMOPOLYMER |

| INNER TEXTURE | ACRYLIC |

| WEIGHT | 525 g/m² ± 5% |

| AIR PERMEABILITY | 9,000 – 11,000 lt/dm²/hour (Dp:200 Pa) |

| THICKNESS | 2.0 mm |

| TENSILE STRENGTH | Warp: 110 kgf/5 cm - Weft: 140 kgf/5 cm |

| SURFACE TREATMENT | CALENDER AND GLAZE TREATMENT |

| OPERATING TEMPERATURE | CONTINUOUS 140°C DRY TEMPERATURE |

| ACID RESISTANCE |

MODERATE

|

| ALKALI RESISTANCE |

MODERATE

|

| HYDROLYSIS RESISTANCE |

EXCELLENT

|

| SOLVENT RESISTANCE |

GOOD

|

| OXIDATION RESISTANCE |

GOOD

|

What is an Acrylic Homopolymer Filter Bag?

An Acrylic Homopolymer Filter Bag is a type of industrial filter media made from 100% acrylic fibers. Known for their exceptional resistance to acidic environments, these bags are commonly used in dust collection systems, particularly where chemical exposure is high.

Thanks to their hydrophobic nature and stable fiber structure, acrylic filter bags offer consistent performance in both dry and moist conditions—a feature that makes them a trusted choice in several key industries.

How is it Produced?

The production of an acrylic homopolymer filter bag begins with high-quality acrylic staple fibers, which are:

Needle-punched into a durable felt media,

Thermally stabilized to improve dimensional strength,

Optionally finished with surface treatments like singing, calendaring, or membrane lamination depending on the application.

The final product is then shaped and stitched using chemical-resistant thread and tailored to fit specific dust collector models.

This process ensures a uniform structure that resists clogging and delivers high filtration efficiency over extended periods.

Durability and Technical Compatibility

One of the main advantages of acrylic homopolymer filter bags is their durability under harsh chemical conditions. Some key features include:

Operating temperature resistance up to 130°C (266°F)

Strong resistance to organic solvents and oxidizing agents

Excellent performance in acidic environments

Good mechanical strength and abrasion resistance

These properties make acrylic filter bags technically compatible with many industrial filtration systems, especially where corrosive gases or vapors are present.

Usage in Chemical Applications

Acrylic filter bags are particularly suitable for chemical processing environments, such as:

Fertilizer plants

Pharmaceutical dust filtration

Acid gas scrubbing

Dye and pigment manufacturing

In these conditions, where many standard filter materials would degrade, acrylic homopolymer media maintains integrity and performance, helping companies stay compliant with emissions standards.

Why Should You Choose It?

Here’s why Acrylic Homopolymer Filter Bags are a smart choice:

- Cost-effective solution for chemically aggressive environments

- Stable filtration performance over long service periods

- Versatile compatibility with various filtration units

- Improved system uptime due to reduced clogging and longer service life

For operations requiring chemical resistance without compromising air quality, acrylic is a balanced and dependable option.

Main Industries Using Acrylic Filter Bags

Acrylic filter bags are used across many sectors, especially in:

Chemical processing plants

Textile and dye industries

Waste treatment facilities

Fertilizer and agrochemical production

Power generation with chemical by-products

Their ability to handle chemically aggressive and thermally moderate conditions makes them a go-to media for filtration engineers.

Fora Filtre: Your Trusted Name in Filtration

At Fora Filtre, we understand that effective filtration is not just about capturing dust—it’s about ensuring safety, efficiency, and sustainability.

With our experience in manufacturing custom-made filter bags, including Acrylic Homopolymer Filter Bags, we offer:

- Tailor-made solutions for your system requirements

- High-quality raw materials and certified production standards

- Responsive technical support and fast delivery

Choose Fora Filtre—because in critical filtration environments, trust matters as much as performance.