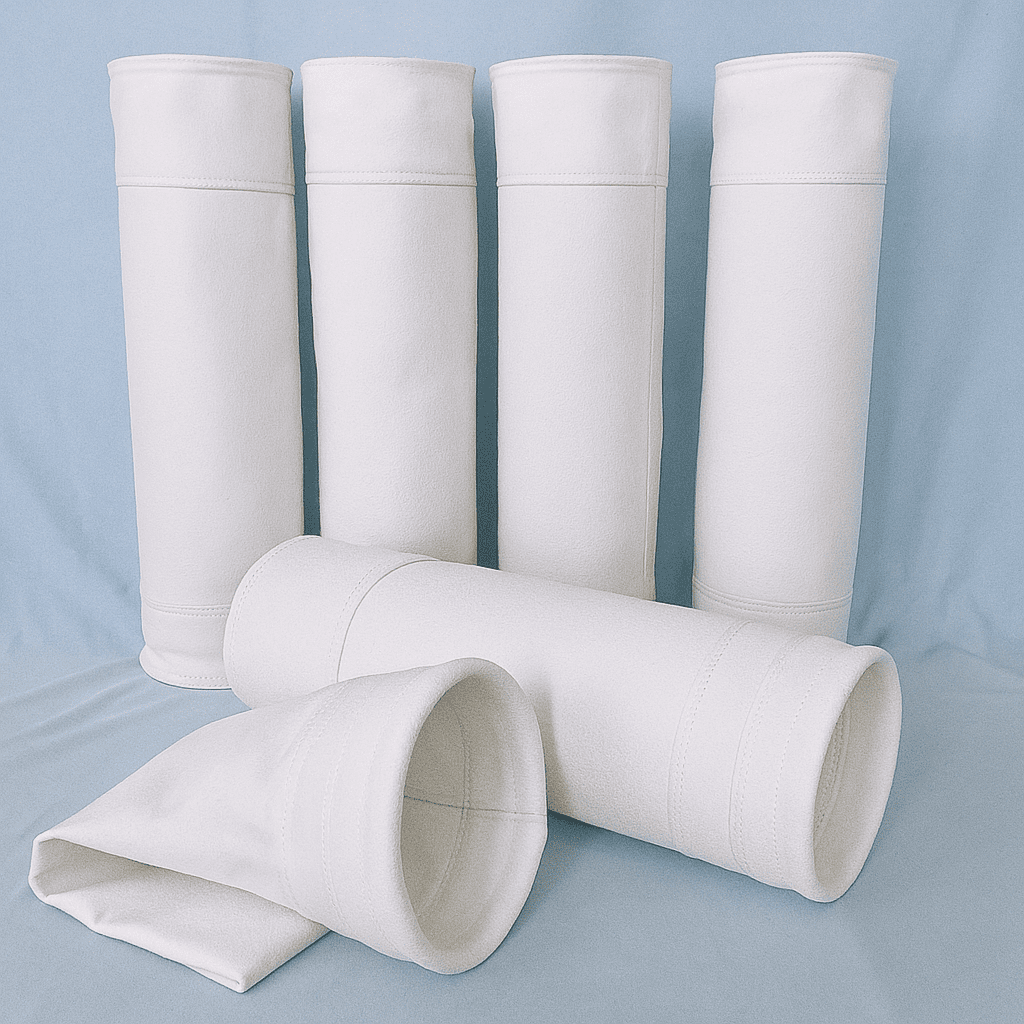

Glass Fiber Filter Bag

- Homepage

- Filter Bag

- Glass Fiber Filter Bag

Glass Fiber Filter Bag Features

| CONTENT | 100% GLASS FIBER |

| INNER TEXTURE | GLASS FIBER |

| WEIGHT | 770 g/m² ± 5% |

| AIR PERMEABILITY | 3,000 – 4,000 lt/dm²/hour (Dp:200 Pa) |

| THICKNESS | 2.0 mm |

| TENSILE STRENGTH | Warp: 150 kgf/5 cm - Weft: 120 kgf/5 cm |

| SURFACE TREATMENT | CALENDER AND GLAZE TREATMENT |

| OPERATING TEMPERATURE | CONTINUOUS 275°C DRY TEMPERATURE |

| ACID RESISTANCE |

GOOD

|

| ALKALI RESISTANCE |

WEAK

|

| HYDROLYSIS RESISTANCE |

GOOD

|

| SOLVENT RESISTANCE |

EXCELLENT

|

| OXIDATION RESISTANCE |

EXCELLENT

|

What Is a Fiberglass Filter Bag?

A fiberglass filter bag is a high-performance filtration solution specifically designed for use in extreme temperature environments. Capable of continuous operation at temperatures up to 275°C, it is one of the most heat-resistant filter bag types available today. This makes it ideal for heavy industrial processes, such as metal smelting, cement production, and thermal energy systems.

Thanks to its excellent resistance to solvents, acids, and oxidizing agents, the fiberglass filter bag offers superior durability in chemically aggressive environments. Weighing approximately 770 g/m², each bag is treated with both hydrophobic impregnation and a glazing (calendering) process. These treatments enhance the bag’s water- and oil-repellent properties and create a smooth surface that helps prevent dust buildup. As a result, the filter system experiences less clogging, more efficient dust discharge, and longer service life.

At Fora Filter, we manufacture fiberglass filter bags in strict accordance with industrial standards. From the selection of raw materials to custom fabrication and post-delivery technical support, we ensure your filtration system performs at its best—no matter how demanding the operating conditions.

Key Features of Fiberglass Filter Bags

Material: Fiberglass needle felt

Operating Temperature: Up to 275°C (continuous)

Weight: ~770 g/m²

Surface Treatments: Hydrophobic and oleophobic impregnation, glazing

Chemical Resistance: Excellent (solvents, acids, oxidizers)

Filtration Efficiency: High particle retention with minimal pressure drop

Service Life: Extended due to low clogging and thermal stability

Where Are Fiberglass Filter Bags Used?

Fiberglass filter bags are commonly used in high-temperature industrial dust collection systems, particularly in facilities where both elevated heat and chemical exposure are present. These include:

Steel and iron production

Cement and lime plants

Incineration and combustion systems

Ceramics and glass manufacturing

Asphalt plants

Chemical processing plants

Power generation facilities

Their unique material composition and structural design make them highly reliable in harsh, continuous-duty applications where traditional filter media may degrade quickly.

Why Choose Fiberglass Filter Bags from Fora Filter?

At Fora Filter, we go beyond manufacturing—we offer complete filtration solutions tailored to your facility’s needs. With deep industry experience, we help you select the right filter bag type based on critical factors such as:

Maximum and continuous operating temperatures

Chemical composition of dust and gases

Airflow volume and system pressure

Type and configuration of your filtration system

Our technical team is ready to guide you through product selection, material compatibility, and system optimization to ensure the maximum efficiency and safety of your dust collection process.

Need Help Choosing the Right High-Temperature Filter Bag?

Choosing the correct filter material is essential for long-term system performance, especially in high-heat and chemically aggressive environments. Fiberglass filter bags are a robust and reliable solution—but only when matched to the right process.

Contact Fora Filter today for expert support. Our team will evaluate your facility’s specific requirements and provide custom-tailored filtration solutions designed for durability, performance, and environmental compliance.