Filter Cages

- Homepage

- Filter Cages

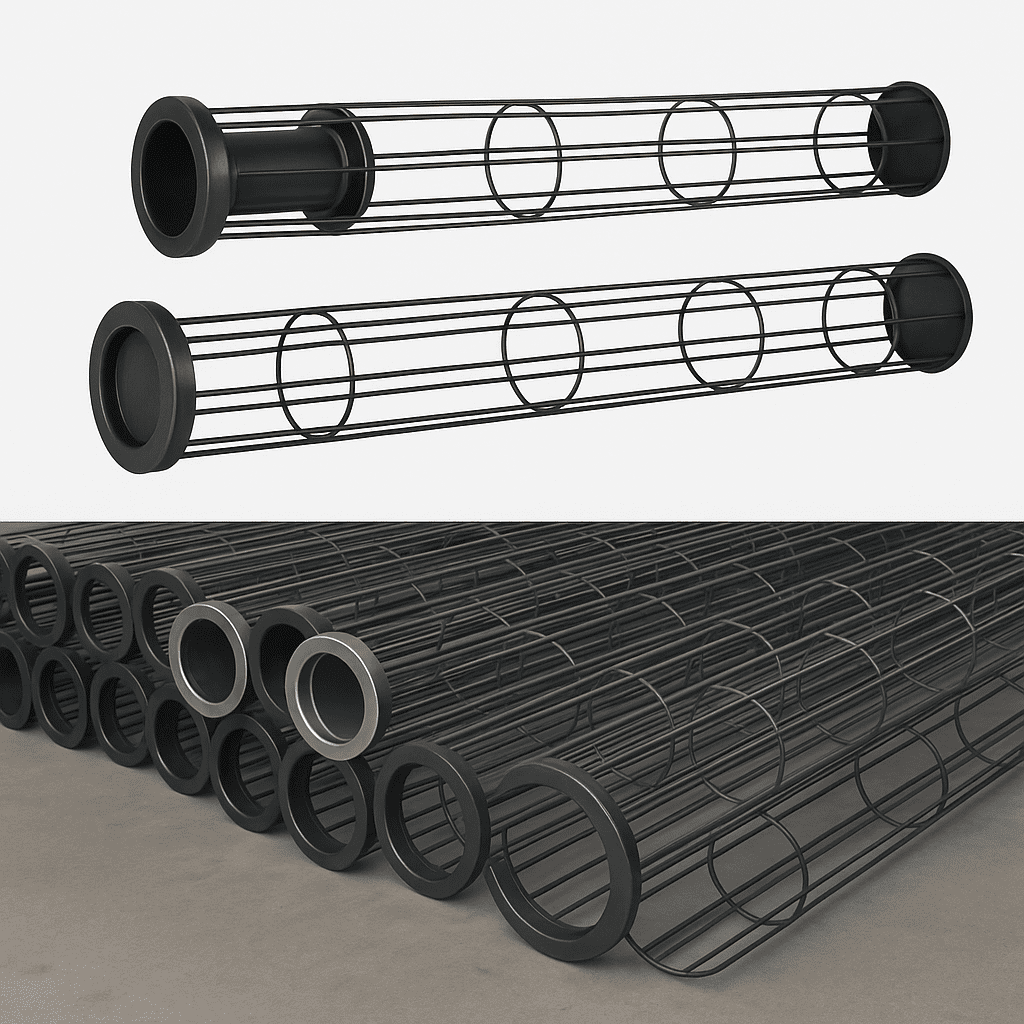

What Is a Filter Cage and What Is Its Purpose?

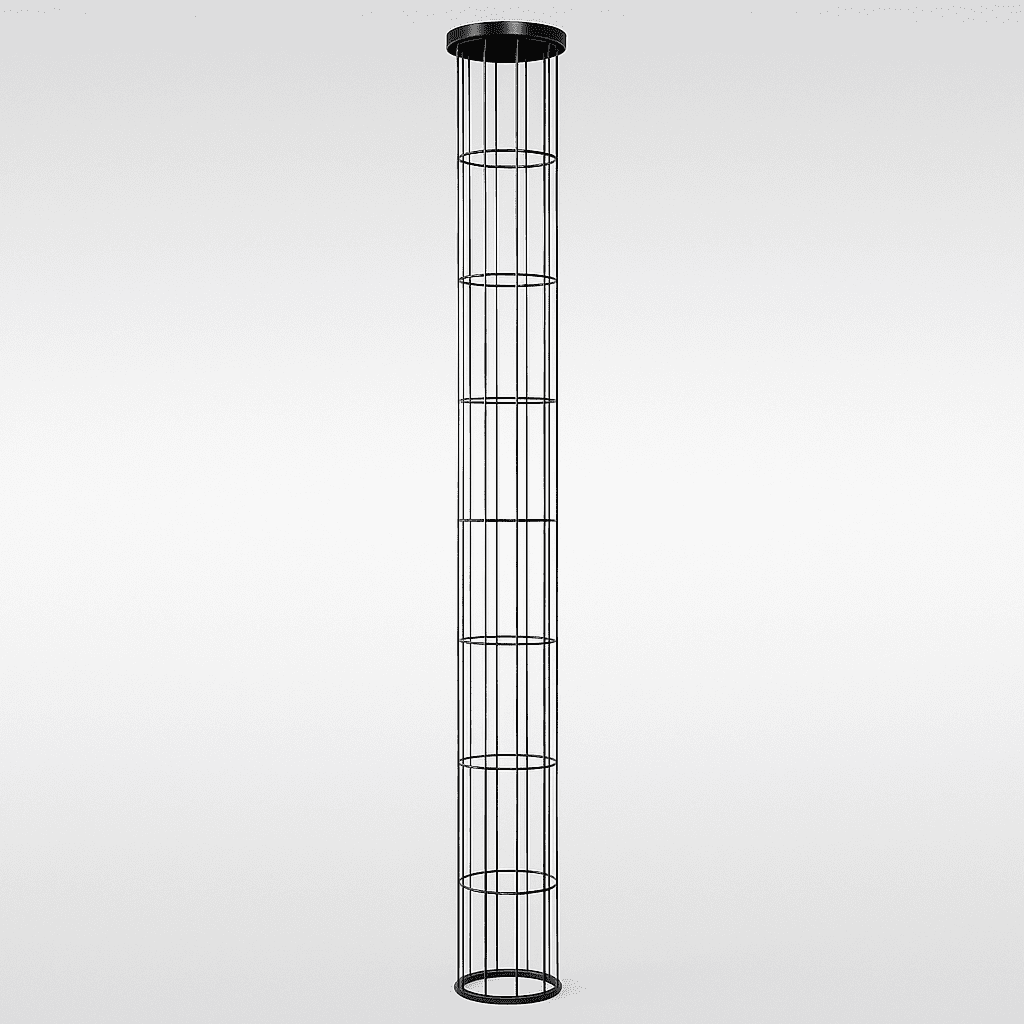

A filter cage is a critical structural component used in baghouse filtration systems. It is designed to support the filter bag from the inside, ensuring that the bag retains its shape and mechanical stability—particularly during jet pulse cleaning cycles, which dislodge accumulated dust from the surface of the filter media.

The primary function of the cage is to prevent the filter bag from collapsing, tearing, or deforming under negative pressure or during high-pressure air pulses. Since every filtration system has its own unique dimensions and process conditions, filter cages must be custom-engineered to match the exact specifications of the filter bags and the system itself.

A key factor in filter cage manufacturing is surface quality. All contact points must be smooth and free from burrs, as sharp edges can compromise the integrity of the filter media—leading to air leakage, reduced efficiency, or premature failure.

Filter Cage Manufacturing Process

The production of filter cages begins with steel wire supplied in coils, which is straightened and cut to required lengths. These steel rods are then assembled into a cylindrical framework using an automatic spot-welding system, ensuring uniform spacing and consistent structural integrity across the cage.

The cage is completed by:

Welding a bottom cap or base ring to provide structural closure

Fitting a venturi nozzle at the top to optimize airflow and enhance pulse-jet cleaning performance

After the frame is constructed, protective coatings are applied to extend the product’s durability:

Electrostatic powder coating for general industrial use

Electro-galvanized coating for applications with high humidity, chemical exposure, or corrosion risk

Each cage undergoes de-burring and quality inspection to ensure a smooth surface and compatibility with the filter media.

Types of Filter Cages and Custom Solutions

At Fora Filter, we design and manufacture a wide range of filter cage types to accommodate various industrial filtration systems, including:

Standard Round Cages

Flat-Type Cages

Oval Cages

Star Ring Cages (especially common in asphalt plants)

All cages are available in custom diameters, lengths, and configurations, tailored to match your system’s technical requirements.

We also offer on-site assembly services upon request, including the installation of both filter bags and cages to ensure optimal system performance and integration.

For more information or tailored support regarding filter cage selection and production, contact our technical team. We are here to provide end-to-end filtration solutions built on quality, precision, and industry expertise.