Air Filter Manufacturing

- Homepage

- Filtration

- Air Filter Manufacturing

Industrial Air Filter Production

At Fora Filter, we specialize in the manufacturing of high-performance industrial air filters, engineered to meet the diverse demands of modern production environments. Our filters are produced using a wide range of advanced materials, including:

- Polyester

- Meta-Aramid (Nomex)

- Antistatic fiber blends

- P84 (Polyimide)

- PTFE (Teflon)

- Polypropylene (PP)

- Fiberglass

- Acrylic Homopolymer

The choice of filtration media is determined by the specific operational conditions of each facility, including temperature, chemical exposure, particle type, and system requirements.

Purpose and Importance of Industrial Air Filters

While air filters are commonly found in household appliances such as vacuum cleaners and air conditioning units, their role in industrial settings is considerably more critical. The main purpose of these filters is to capture airborne dust and particulates before they are released into the environment, thereby:

- Protecting human health

- Preserving equipment functionality

- Ensuring environmental compliance

- Promoting workplace safety

In today’s high-capacity manufacturing sector, the release of untreated, particle-laden air can lead to significant ecological damage and occupational hazards. As such, industrial air filtration systems are no longer optional but essential.

Unlike residential filters, industrial air filters must perform under much more demanding conditions—where extreme temperatures, chemical vapors, and abrasive particles are common. This necessitates the use of engineered filter media, tailored specifically for each application.

How Industrial Air Filters Are Manufactured

The production of industrial air filters at Fora Filter involves a sequence of precision-controlled steps:

- Material Selection

Each filter begins with the careful selection of the appropriate base material. This decision is based on key factors such as:

- Operating temperature range

- Resistance to acids, alkalis, oxidation, solvents, and hydrolysis

- Airflow dynamics and particulate characteristics

- Needle Punching Process

Selected fibers are processed in needle punching machines, where they are mechanically entangled to form a durable and permeable nonwoven filter fabric suitable for industrial use.

- Surface Treatments

To enhance performance, the filter fabric undergoes the following treatments:

- Hydrophobic & Oleophobic Impregnation

Provides resistance to water, oil, and moisture. - Glazing (Gaze) Process

One surface of the fabric is smoothed to prevent dust adhesion and improve airflow. This step also enhances the cleaning efficiency of the filter during pulse-jet operation.

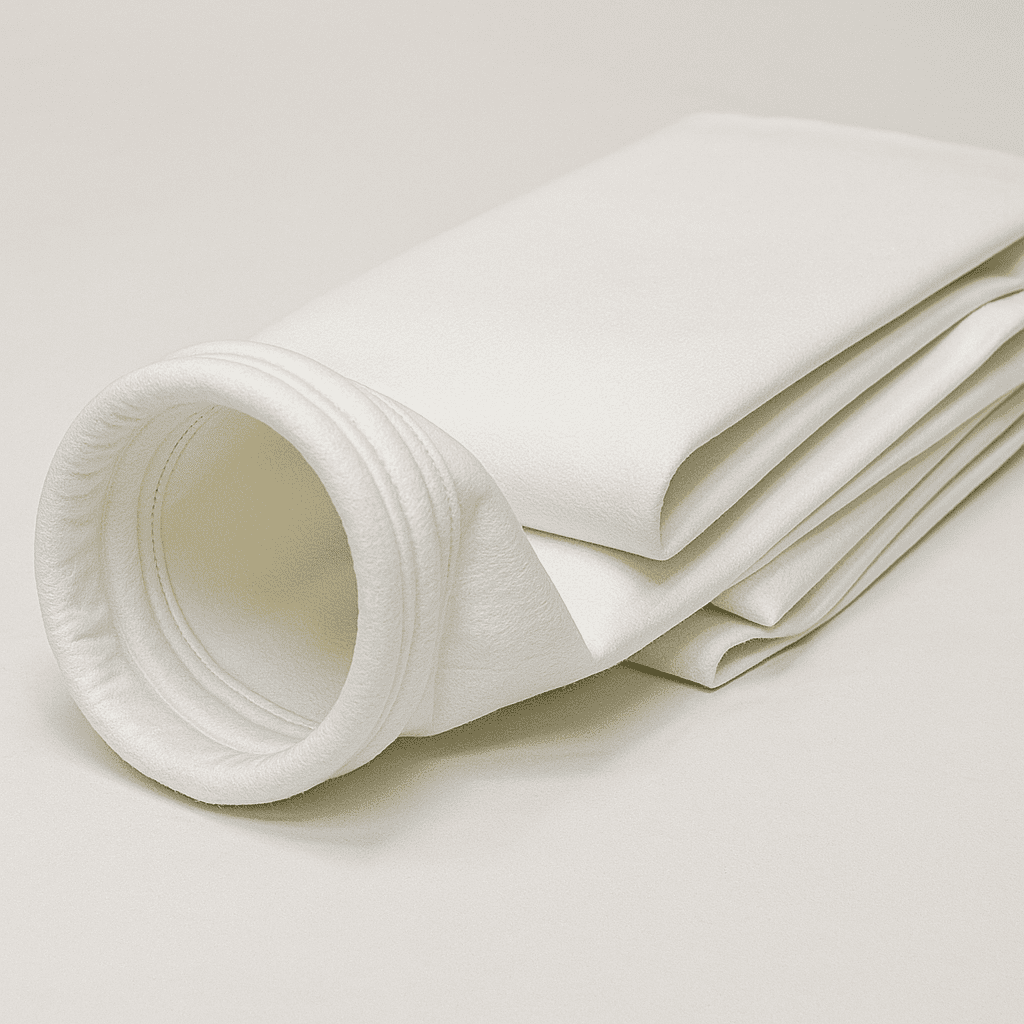

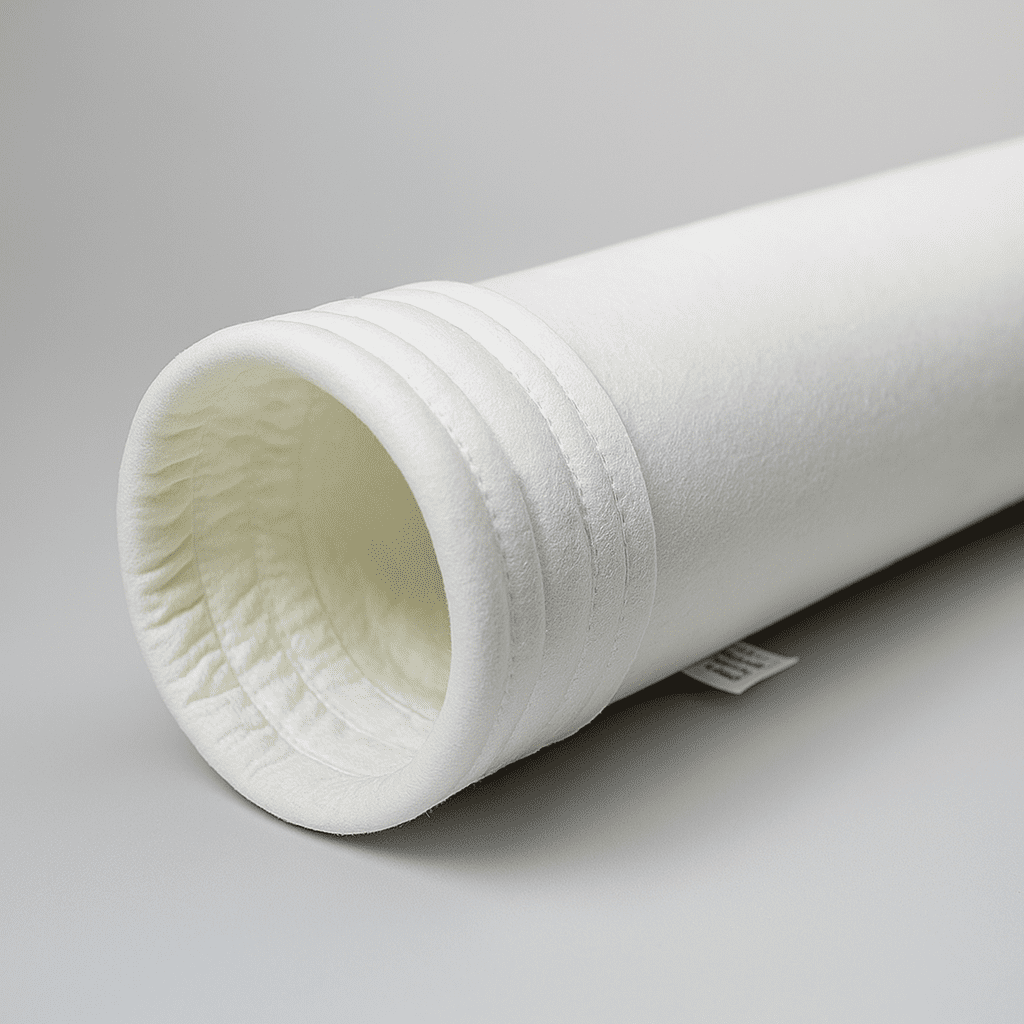

- Cutting and Assembly

The treated filter fabric is rolled, cut to specified dimensions, and prepared for assembly. Using high-tensile chain-stitch machines, the fabric is sewn into cylindrical filter bags.

- A sealed cap is attached to the bottom.

- A reinforced collar is sewn to the top for secure integration with the filter cage and venturi system.

- Final Inspection and Packaging

Each filter bag is trimmed, inspected, and cleaned of excess threads before being packaged and prepared for delivery. All products undergo quality control procedures to ensure compliance with technical and performance standards.

Custom Solutions for Industrial Needs

At Fora Filter, we understand that every facility operates under unique conditions. That’s why we offer tailor-made air filter solutions, manufactured in custom sizes, shapes, and material compositions.

Whether you’re operating in the cement, steel, food processing, chemical, mining, or recycling sector, our engineering team is ready to help you identify the most effective and cost-efficient air filtration system for your needs.

Contact Us for Technical Consultation

Need help choosing the right air filter for your system?

Our technical specialists are available to assist with:

✔ Material selection

✔ Design customization

✔ Technical support and cost optimization

Email: info@forafilter.com

WhatsApp: +90553 636 4071

Fora Filter—your trusted partner for clean air, efficient systems, and sustainable industrial performance.